We are very proud of our soundproof floor panels SONO/MAX 25.

For any questions or additional information regarding the installation, do not hesitate to contact us.

Please follow the instructions in order to benefit from our product’s superior insulation capacities :

Short installation sheet

Preparation

IMPORTANT : Before opening the package, let the SONO/MAX25 sit for 24 hours in the room where it will be installed. Make sure the room temperature does not go below 18C (64F).

In order for the installation to be optimal, make sure that the subfloor (concrete slab) is completely flat. There should be no undulation or irregularities on the floor surface. Using a ruler or a level, check to see if the subfloor (concrete) is 3/16" thick over a length of 10' or 1/8" thick over a length of 6”. If there are irregularities to be fill, be sure to use a cement-based filling compound with a capacity of 3000 lb/in.

Recommandations: Make sure to not exceed the maximum thickness recommended by the manufacturer. Otherwise there could be too much filling product and the filling would not be strong enough to support heavy objects. Once again, make sure that the subfloor has no imperfections (including screws and nails).

Recommandations: Fill all cracks and remove all residue if installed on a concrete floor. In the event that you install it on a wood structure, make sure that the structure respects construction norms. All surfaces must be clean, dry, and ruggedness.

Install a 6mm polyethylene on the floor to be covered if recommended by the manufacturer.

Installation

SONO/MAX under 3/4 engineered wood (nailed) 12

When installing, always leave at least 1/2 "between the SONO / MAX system and walls, ducts, columns, etc.

First row: Cut the panel in half lengthwise (5 "x 48"), the textured side up, and insert the profiled lath. The batten must extend beyond the panel joint by at least 8 ".

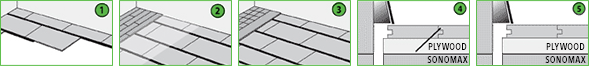

Following rows: Alternate the panels in steps. 1

A plywood sheet of at least ½" will need to be installed and screwed prior to laying the wood over the SONO / MAX 25.

Install a vapor barrier paper (waxed and translucent) between the SONO / MAX 25 and the wood (for new construction with a concrete structure).

To attach the hardwood, use only 1½" pins, which should not come in contact with the subfloor.

Before installing the wood floor on the surface, read and follow the instructions of the manufacturer of the product.

SONO/MAX 25 under floating engineered wood or under laminate (floating) flooring 2

When installing, always leave at least 1/2 "between the SONO / MAX system and walls, ducts, columns, etc.

First row: Cut the panel in half lengthwise (5 "x 48"), the textured side up, and insert the profiled lath. The slat must extend beyond the panel joint by at least 8".

Following rows: Alternate the panels in steps. 1

Before installing the wood floor surface, read and follow the instructions of the manufacturer.

SONO/MAX 25 under ceramic, marble, or granite (with spacing of a support panel)3

When installing, always leave at least 1/2 "between the SONO / MAX 25 system and walls, ducts, columns, etc.

For laying ceramic or natural stone: always leave at least 1/2" between the SONO / MAX 25 system and walls, ducts, columns, etc.

Install SONO/MAX 25 on the floor as shown in picture 1

For ceramic tile, screw the 3/8" thick Fiberock floor boards every 6" with floor screws of 1" No10 floor screws. Make sure the screw head stays on the surface of the support panel to prevent the screw from touching the subfloor.

Apply 4 "alkali resistant fiberglass tape and cover tape on all joints with a thin layer of cement glue.

Use the mortar recommended by the manufacturer for the installation of ceramic, marble, and granite.

Replacement of the concrete screed with SONO/MAX 25